Vignettes of Early Radiation Workers

[MUSIC PLAYING]

INTERVIEWER: This is another of the series entitled, Vignettes of Early Radiation Workers, sponsored by the Bureau of Radiological Health. These consist of unrehearsed interviews with scientists, working mostly in fields that impinge upon the applications of ionizing radiation to diagnostic and therapeutic radiology. Such fields include biology or radiobiology, physics, radiological physics, engineering, embryology, endocrinology, and many others.

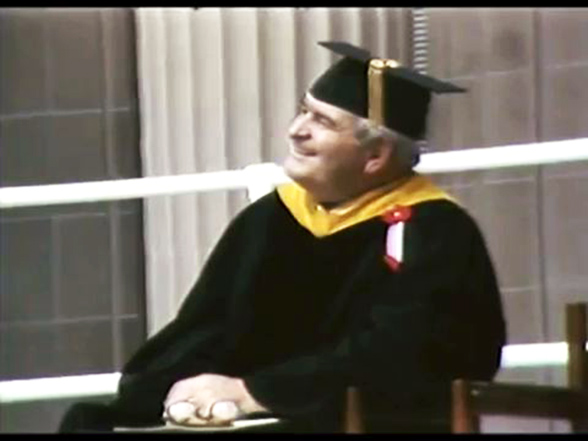

But today, we have with us an engineer who typifies that American capability of converting great ideas into operating mechanisms that can then be turned over, as it were, to the man in the street for safe and proper use and applications. Only Professor John Trump, who is with us today, did not stop there. He carried further the development of high-voltage, radiation-producing machines, making them available for research applications.

And in at least one of these, the technology of medicine, he has also pioneered in some of the research, and we'll hear about some more of these as we go along. John, I'd like to start off by asking each of our visitors where they came from, how they happened to get interested in their field, and so on. This is always of interest to the young people.

TRUMP: I was born in 1917, the youngest of three children in the borough of Bronx of New York City, but grew up in Woodhaven on Long Island. When I graduated from Richmond Hill High School, I went to work after seeking a job in an architect's office at the Western Electric Company in New York City Western Bethune Street. That was in 1923.

INTERVIEWER: Well, this is the second time among my friends here that I've discovered that I almost overlapped at the same laboratories with you. I was there in 1922 for almost a year.

TRUMP: I wished I would have known that.

INTERVIEWER: Well, it would have been fun. Tell me. As a boy, did you do things or have any particular interest in matters that we would now describe as of an engineering nature and so on? Did you have a shop and so on?

TRUMP: I had some very primitive beginnings in that direction and inclinations, I think. As a boy with my brother, two years older, we did many things around the house in the way of maintenance and duties.

INTERVIEWER: Oh, yes, well, so you went to Brooklyn Polytechnic Institute, and there you got your undergraduate degree. Was that correct?

TRUMP: That's right. I got there in 1925 and graduated in '29 and remained for two years as instructor in electrical engineering. The impetus to go to Brooklyn Poly came while I was working at Western Electric, which changed its name to Bell Telephone Laboratories while I was there, as a result of meeting Edward [? Shore, ?] who later became a professor of physics at the University of Chicago. [? Shore ?] urged me to get a college degree in engineering and recommended Poly.

INTERVIEWER: Ah, well, it's been a great school. From Poly, you went then to MIT to pursue your graduate work.

TRUMP: Yes, I did. There was an intervening two years. While I was an instructor at Poly, I studied physics at Columbia University and got the master's degree there.

INTERVIEWER: While I was working at the Bell Laboratories, I went to night school at Columbia and then later, after I was through at Cornell, went back and worked for a summer there with Bergen Davis and Floyd Richtmyer.

TRUMP: That's very interesting. I took a course in radioactivity under Bergen Davis.

INTERVIEWER: Oh, he's a great guy.

TRUMP: He certainly was.

INTERVIEWER: A great guy, yeah, now, when you went to MIT, I believe your original intentions, if they may be so described, was to go into electric power types of applications. Is that right?

TRUMP: That's right. I had become interested in the design of electric-power machinery, and MIT had a good team of professors in the Department of Electrical Engineering. I came there primarily to become a good designer of high-power, electrical machinery. However, in the process of looking for a doctorate's thesis, I selected a suitable topic in my area and went to see Vannevar Bush, who later became director of the Office of Scientific Research and Development.

Bush heard me on my problem, and then he said, you ought to go and see Van de Graaff. He has just arrived at MIT from Princeton, and he has some wild ideas. But I've checked a few of them, and they stood up.

INTERVIEWER: Bush said he had checked a few of them.

TRUMP: Bush said that, yes. So the next morning, I went to the indicated room in the new physics building at MIT. I expected to find an old Dutchman with a white Van Dyke because Van was already famous.

I knocked on the door and entered. The room was empty, except in the far corner, there was a young man. That couldn't be the great Van de Graaff. And I said, with a voice peppered with disappointment, I was looking for Dr. Van de Graaf. And he said, in a soft, Alabama tone of voice, I am he.

INTERVIEWER: Yeah, I had loved to listen to him.

TRUMP: So that began an association which persisted as long as he lived. He was my mentor and great friend.

INTERVIEWER: But as it turned out-- and I'll come back to that later-- your thesis did not end up in connection with these developments of the Van de Graaff ideas.

TRUMP: After testing Van's wild ideas-- that's in parenthesis-- for six weeks, I decided they were plausible and reasonable, and I abandoned the design of electric machinery and began studying the installation of high voltages and vacuum. Van was very much interested in vacuum and the acceleration of heavy particles to high energies. And my thesis was on vacuum electrostatic engineering, that is the insulation of rotating electrostatic machines in high vacuum.

INTERVIEWER: Well, and during that particular period, quite a few people in the country and, in fact, in the world were pushing hard to get to higher and higher voltages on their accelerators, primarily for studies in nuclear physics.

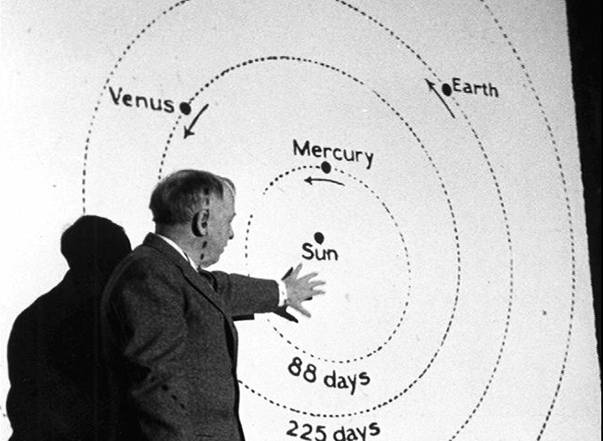

TRUMP: That is true. Van, he while he was a Rhodes Scholar at Oxford, had been inspired by Rutherford to think up some better way of getting extremely high, constant voltages for nuclear particle acceleration, and it was while he was at Oxford that he thought up his electrostatic bell generator, which revolutionized the acquisition of high DC voltages. And while he was then at Princeton, where Dr. Karl Taylor Compton was head of the department, he suggested to Van that he develop this method. And he was brought to MIT after producing a model which went up to a million volts. Actually, they were two half-million-volt generators, looking at each other.

INTERVIEWER: I see. Now, I think that when he-- and you can correct me on this-- when he first came up to MIT, this led to the establishment of the so-called Round Hill generator. Is that correct?

TRUMP: That is correct. In about 1931, I think, or late '30, he came to MIT, following Dr. Compton, in fact, who had become president of MIT. And he undertook, as you might say, his second model, the Round Hill accelerator. That was 70 miles south of MIT. This was a huge double electrostatic generator, with spheres which were 15 feet in diameter, set on a [INAUDIBLE] pedestal, 25 feet high. Two huge machines, one was to run positive, and the other, negative.

INTERVIEWER: So you had at the top your two spheres or whatever the shape was. I have forgotten.

TRUMP: Spherical.

INTERVIEWER: Spherical, one at plus and one at minus. So between the two, you had your total voltage.

TRUMP: Yes, these two generators were mounted on a carriage which moved on railroad tracks, so the gap between them could be changed.

INTERVIEWER: Yes, right, I remember that now. I've sort of forgotten some of the details of it. I think you had no direct involvement with that at the time, but it was later moved up to the MIT campus where you had some peripheral interest with it.

TRUMP: Yes, my involvement with that generator and accelerator system was always peripheral. At Round Hill, Lester and Chester Van Atta worked with Van de Graaff to build it, and at Round Hill, they produced 5 and 1/2 million volts between the two terminals. And they did stretch a horizontal evacuated tube between the two terminals, but that particular effort was not successful, partly because the radiation efforts were so high, but partly, also, because there was a radiation problem in the terminal.

I did visit Round Hill in the early days when it was first being turned on, on a weekend once or twice, and on one of these occasions, I believe I might have been the first one to be in the terminal when it was energized. It happened late at night, about 10 or 11 o'clock, in this dark blimp hangar, and I was sent up, armed with a heavy ball-peen hammer, to knock on the aluminum sphere in case the paper belts showed any tendency to run off the pulleys and tear. And on this occasion, they had to succeeded in drying the belt sufficiently so that it did develop voltage and did carry charge up to the terminal.

And shortly after they started the belt and then actuated the corona system, a terrific sparkover took place from the edge of the two-foot opening through which I had come to a roof rafter, 20 feet away, and since I experienced no physiological reaction, I realized, which I hadn't fully believed before, that Michael Faraday had been right.

INTERVIEWER: John, I had a very similar experience to this and spent a good many hours in the cap on top of our 1 and 1/2 million volt generator that we had then at the Bureau of Standards, and I was always very grateful to Michael Faraday for having developed his theories about electric fields inside of closed containers, such as the caps that we used on our tubes. Well, let's move on. In connection with your generators, then out in air, you had problems with voltage measurement. What did you use for voltage measurement in those days?

TRUMP: The standard way of measuring extremely high voltages was to use sphere gaps. The sizes of the spheres went up appropriately as the voltage raised, and they were pretty big, like a meter in diameter for the million-volt range. But the next, or superior, way that came along was the generating volt meter, which involved rotating a sectored disk in front of collector plates, exposed to the field from a ground potential region. I was quite interested in the development of generating volt meters, but had only made minor contributions to that art. It's a very superior instrument. We also used a variety of high-voltage resistors to measure high voltage. The poor man's way of doing it in those days was to take a glass tube and fill it with an appropriate mixture of xylene and alcohol, so as to be a good, low-current, high-voltage resistor.

INTERVIEWER: Well, those seem to be the standard things of those days. Everybody must've learned from everybody else what to try. Well, all right, so without going into too much detail with regard to these then-called belt generators, you actually moved rather quickly, I believe, into some practical applications, and I have with me a couple of photographs here of one of the early medical installations made at the Huntington Hospital in Boston.

TRUMP: Yes, in 1935, we got the opportunity to build a million-volt x-ray therapy source for the Huntington Memorial Hospital in Boston. This is a picture of the machine, which came into clinical use in March of 1937, about two years later. It was funded by a grant to Harvard University by the Godfrey M. Hyams Trust.

Being an air-insulated machine, of course, and aimed at producing, which it did, a million volts DC potential, it was rather large. The metal-clad room in which it was housed was 20 feet high and about 25 foot square. This aluminum terminal has corners which were quadrants of a 5-foot-diameter aluminum [INAUDIBLE].

And you see it's well rounded in its sections and its horizontal-- its sections. The belts, there were six runs of belts, each 3 foot wide, running a mile a minute to produce a total current of about 4 milliamps, and this acceleration tube has 20 individual sections, for a total accelerating length of 10 feet.

INTERVIEWER: Could your tube actually stand 4 milliamperes, the target?

TRUMP: We never used 4 milliamps. When it began operating, we got an x-ray output of the order of 50 roentgens per minute at a meter's distance with one milliampere at a million volts. 4 milliamps was something near the top short-circuit current that this electrostatic generator can produce. And this man is Dr. Richard Dresser, who was the radiation therapist of the Harvard Medical School at the Huntington Memorial Hospital. The tube was a vacuum, a mercury vapor continuously pumped system.

INTERVIEWER: Well, now, what did that look like at the patient end of the tube? I think you have a picture of that.

TRUMP: Yes, I do have a picture of that. The grounded end of this million-volt tube extended into the treatment room below, and this shows the lead-surrounded, grounded tube, which terminated in those days in a water-cooled led target. As you well know, it should be a high atomic number, and lead was both cheap and had a very high atomic number, which assists in the conversion into x-rays. This concrete-shielded room, which was underground, was nicely decorated with pictures from the Fogg Museum, on loan from Harvard. And Dr. Dresser used these million-volt radiations for about five years, until the Collis P. Huntington Hospital was closed by Harvard University, and got very interesting results. He observed the remarkable skin-favoring characteristic of these more penetrating x-rays and found also that he got a much better depth dose in treating deep tumors.

INTERVIEWER: Well, that particular piece of equipment served its purpose very well and certainly laid the foundation for what was to come later, but also, I think, rather well demonstrated that it was perhaps not the most practical thing to have that kind of enormous installation for each therapeutic installation. So this lead you, then, into the development of compressed gas belt generators.

TRUMP: That's true, yes.

INTERVIEWER: Tell me a little about that.

TRUMP: We became convinced during this period that the superior way to insulate the high voltages desirable for x-ray therapy was to use the superior insulating qualities which gases get when they are compressed to high pressures, not only ordinary gases like nitrogen and CO2, but even special gases, those containing the halogens, of which, today, sulfur hexafluoride is the most attractive one. And this shows the next proposal, this time to the Massachusetts General Hospital, for a Van de Graaff x-ray source which became operative in the spring of 1940. This machine operated at a higher voltage than Huntington, 1.4 million volts.

INTERVIEWER: Now, let me call attention to the fact that that machine is about the height of a man. The other one at the Huntington must've been the height of about four men or something of the sort.

TRUMP: It was very much smaller. In this case, the acceleration tube is within this insulating column and is 4 feet long, instead of 10 feet long. And the high-voltage terminal, instead of being 15 feet by about 10 feet in dimension, is only about 30 inches in diameter. So everything was much smaller. Of course, the enclosing tank, which housed the compressed gas, nitrogen and CO2 mixture at 10 atmospheres, is removed in this picture.

INTERVIEWER: How long was that tube in use at Massachusetts General Hospital?

TRUMP: This was used for about at least 16 years, somewhere between 16 and 18 years, and finally the gold x-ray target was presented to me in a solid block of Lucite, as a permanent memory.

INTERVIEWER: Great, well, I have another step in this development. This was a unit that you built somewhat the same as this other for, I believe, the American Oncologic Hospital in Philadelphia. Is that correct?

TRUMP: Yes, the American Oncologic Hospital became interested in acquiring x-rays which were characterized by the greater penetration and lower skin effects, which were now convincingly demonstrated, and we undertook to develop a 2 million volt machine, which was even smaller than the Mass General. This shows my associate, Robert Cloud, who did an outstanding research and development job with me in the High Voltage Research Laboratory at MIT. This picture was actually taken at the end of World War II.

I became involved in war activities beginning in 1940, but Bob Cloud continued to work on x-ray development. And this shows the acceleration tube, which is now somewhat sealed off, partially sealed off. The tube length is only 24 inches for 2 million volts.

This machine also operated at the Oncologic Hospital when it was finally installed in 1947 for a long time, something like 16 or 17 years, and is now at the Countway Library of Harvard University as a historical relic. The first model of this was actually requisitioned by the US Army for the Manhattan Project, for radiation effects studies on materials needed in the then-top-secret Manhattan Project.

INTERVIEWER: You know, I'm delighted at your decision to send that to the Countway Library or some such place because all too often these things, having served their initial purpose, are moved to one side and junked and lost forever. You just must continue to send some of your things to places like that.

TRUMP: That's right.

INTERVIEWER: Oh, you must. Well, incidentally, what voltage did that machine run at? Was that another--

TRUMP: It was used at 1.75.

INTERVIEWER: 1.7, so you went from 1 to 1 and 1/4 to now 1 and 3/4, essentially.

TRUMP: Right, mm-hmm.

INTERVIEWER: And, of course, the things were getting more reliable and useful all the time. Well, there were varieties of rather special problems in connection with these developments. Let me ask you about a couple of them. One was the question of the tube construction. That is the x-ray tube or accelerator tube. How were those made up?

TRUMP: Well, you've put your finger on the heart of the problem. The acceleration tube has been the most difficult component to produce for not only x-ray sources but also high-energy electron sources and positive ion sources for nuclear research. It was made up by a cascade system of tube construction in which alternations of porcelain or glass-- it began with porcelain and was replaced by glass, which is superior as an insulator-- and metal electrodes, so that the total voltage between the cathode and anode was evenly divided between these sections.

The seal, of course, was a problem, and the seal we developed at MIT-- and Robert Cloud was a principal in developing the technique-- was to use a thermoplastic seal, [INAUDIBLE]. It's an organic material which you can paint on, and it hardens on both the metal electrode and on the porcelain or glass surface. And after it's dry and the solvent has been removed, you stack the tube and then heat it to an appropriately high temperature so that a thermal union is made, which is vacuum tight.

INTERVIEWER: And then, would that joint be strong-- well, I guess it was. It must've been strong enough so that the tube could be in any position.

TRUMP: Yes, ultimately, those tubes were positioned in horizontal position and in cantilever, so it's a very strong joint. And it's a very good vacuum-tight joint.

INTERVIEWER: I sure wish I'd known about that procedure back in the mid '30s.

TRUMP: Ultimately, the highest voltages produced in acceleration tubes have been joined by this technique, although other techniques which do not involve organic seals have been developed.

INTERVIEWER: Now, these pumps, these tubes, particularly in the early days, operated on continuously-operating vacuum pumps. There were some more problems.

TRUMP: That's true. The vacuum pumps were part of the problem. Dr. Van de Graaff believed one should use an inorganic pumping medium, like mercury, and we stuck to mercury and liquid air trapping as a method of pumping vacuum tubes and also for our high-voltage vacuum studies, which continued for many years. But, of course, low vapor pressure oil pumps were also developed, and with good trapping, they would work, sometimes with higher speeds than you readily got from mercury pumps.

INTERVIEWER: I think you mentioned a little earlier that when you finally chose a thesis subject, it had to do with the vacuum systems which you applied in the making of these tubes. Was that correct?

TRUMP: Yes, I learned about vacuum technique by studying the mechanisms which contribute to failure between electrodes in high vacuum. These mechanisms are many. Dr. Van de Graaff taught me that vacuum was the ideal medium because it was not dependent on the inconsistencies of any material media between the electrodes. But we learned after several decades of study that the electrodes, themselves, became the troublemakers. Emission of ions from the anode surface and also electrons and ions from the cathode surface and the effects of submicroscopic irregularities on the cathode surface have a very fundamental effect on the ability to insulate high voltages.

INTERVIEWER: You know, I suddenly had an idea. If you were to make one of these setups out on the moon, you could have your belt generator set up between two points and no tube in between.

TRUMP: Exactly, yes.

INTERVIEWER: Wouldn't that be something smart?

TRUMP: When the space program began, a great deal of interest was displayed in the fact that our little planet is surrounded by high vacuum superior to anything we can produce in a tank, and we did do some further studies on some of our rotating, vacuum-insulated, electrostatic machinery, which might make very efficient power sources for space satellites.

INTERVIEWER: Well, I didn't mean to get off into that particular subject. It could be a lot of fun. We'll spend an hour with it someday.

TRUMP: Good.

INTERVIEWER: I would like now, though, to get to some of the research that you were involved in, which really was the medical applications of these generators. And one of the things in particular that I know that you were involved in had to do with-- remember the problems of rotational therapy using these high-energy machines? And there you have a couple of photographs of that. Do you want to tell us about that a little bit?

TRUMP: Yes, we became interested after the war-- that is beginning in 1946-- no longer with the problem of developing megavolt x-ray sources, but with the problem of closing the gap between the radiation therapist and the manufacturer of high-voltage x-ray equipment. It was clear that superior methods of applying the radiation so as to deliver the dose where the clinically-trained person, the radiation therapist, believed it should go, this gap and avoiding the treatment of uninvolved, normal structure, which might be around the tumor-invaded region, this gap needed to be closed. So we combined an idea which probably has been quite old and was being used with low-voltage machines, that of rotating the patient in such a way that the x-ray therapy beam always passed through the involved region but by the rotational division only fractionally passed through the surrounding, normal tissue. This shows the treatment distribution or dose distribution you get when you treat an intrinsic cancer of the larynx, a procedure which a long time ago used to require the surgical removal of the vocal cords and which could be very neatly irradiated, with no permanent damage to the voice or vocal cords, by rotational therapy.

INTERVIEWER: But now you have another one there, I think. I've forgotten what that is.

TRUMP: Then, after we worked out rotational techniques for treating many types of tumors-- tumors of the head and neck, tumors of the chest, and tumors of the pelvic cavity-- and this program developed and was carried on at MIT with the wonderful cooperation of the physicians of the Lahey Clinic in Boston. It began in the fall of 1949. We began to develop methods whereby we could protect certain special structures within the rotational field which might have special sensitivities. This particular picture shows diagrammatically how, in rotational therapy in which the x-ray source is a horizontal beam proceeding from this point and is directed toward the region of the upper chest, the spinal cord can be protected by rotating a curvilinear led cord, shaped to throw a shadow upon the spinal cord for all of the angular positions of the patient.

INTERVIEWER: That was a lead shield, shaped and contoured as the spinal column, and as the patient was rotated, this would rotate appropriately so as to provide a continuous shield?

TRUMP: Exactly, it rotated synchronously with the patient.

INTERVIEWER: I don't even believe it, except I know it worked.

TRUMP: It was tailored for each patient, and during the fractionated treatment, which might last four or five weeks, it had the patient's name on it and could be readily positioned in place in a few minutes so as to follow the same position with each daily treatment.

INTERVIEWER: That's remarkable.

TRUMP: Well, we carried this idea of selective protection of sensitive organs in radiation therapy to other conditions. The kidneys, as you know, have a very low tolerance for x-rays. And in some types of malignancies, such as cancer of the ovary, you might have widespread abdominal involvement.

It might be best, in order to deliver a hopefully curative dose to the patient, to treat the whole abdominal region except for the presence of the kidneys, and this shows the same synchronous protection idea in which two cylinders of lead are located so that they throw a shadow on the kidneys, one for each kidney. They rotate synchronously with the patient so that each kidney is followed with by a shadow. It reduces the dose by a factor a little greater than two, enough to permit a curative dose to the surrounding region.

INTERVIEWER: Now, are these techniques still being used?

TRUMP: These techniques are still being used at the Lahey Clinic, and they're quite easily applied. They would not fail to use those in cases where there is the possibility of doing some late damage to a normal but sensitive tissue structure in the treatment field, but it is not a widespread technique. Other methods which approximate this are being used.

INTERVIEWER: Now, this is another example of the procedures which I say are so complicated that they can't be done. The only thing is you did them.

TRUMP: They are quite easy to do, but the general verdict was it was too difficult to do in a busy clinic.

INTERVIEWER: Yes, now, how about the use of high-energy x-rays-- again, we're talking about the million-volt region-- for diagnostic purposes?

TRUMP: We soon learned that although the diagnostics x-ray range--

INTERVIEWER: Can you hold that up a little, there.

TRUMP: The diagnostic x-ray range is, say, up to 50 or 100 kilovolts, typically. Even 1 million or 2 million or even 3 million volts does give a good diagnostic picture, and the radiologists at the Lahey Clinic believe that in taking radiographs of the chest, you can pick up an abnormality near the edge of the mediastinum easier with a megavolt x-ray than with a diagnostic x-ray.

INTERVIEWER: Now, is this in part at least because of the very much diminished scattering?

TRUMP: Mostly because of diminished scattering, that is the really important effect. The scattering is much less. This shows a double exposure of a patient with bronchogenic carcinoma, cancer of the lung. You can see the pathology on this side of the lung. You can see the air passages very clearly.

The double exposure is, first, the treatment field, which was used to include not only the primary tumor but also its extensions to the lateral chest wall and its probable extensions down the mediastinum. That's the darkened region, and then we remove the restrictions, which shaped the field and gave a second exposure to assist in positioning, observing the accurate positioning of this treatment field on the patient. This was not treated rotationally, but by alternate, anterior-posterior multiportal treatment. That is from the back and from the front of the patient.

INTERVIEWER: Now, to shift gears here slightly, this has all been x-rays so far, but beginning in 1950 or thereabouts, you also began to look into the applications of electron therapy.

TRUMP: That's true. In 1952, we treated our first patient who had a very involved case of mycosis fungoides, also called lymphoma cutis nowadays. It represents a malignancy of the skin lymphatic system. It's limited primarily to a region within a centimeter of the skin. It's below the skin and on the skin.

This is a very radiosensitive type of malignancy, and it had been kept under control for some years by the Lahey Clinic physicians using soft x-rays. But now his skin tolerance had been exhausted, and his blood levels were bad. And it was blossoming out over his entire 20,000 square centimeters of skin.

And we treated this man with an extensive-- that is, a total-skin-- treatment of electrons, directly injected into this total skin area. This treatment was given over a two-week period to a dose of about 600 rads. And to our delight and surprise, but especially to his, his skin cleared up. And he was 75 years at the time. He lived to the age of 80 and died of unrelated causes.

INTERVIEWER: I wish we could have shown some pictures of that, but I don't think they would have projected too well at this point. Let's move on to another aspect of the same problem. We've talked now about high-energy x-rays and low-energy x-rays, then also by now, radionuclides were coming into being. Could you discuss a little bit of a comparison of some of the properties of those general radiations?

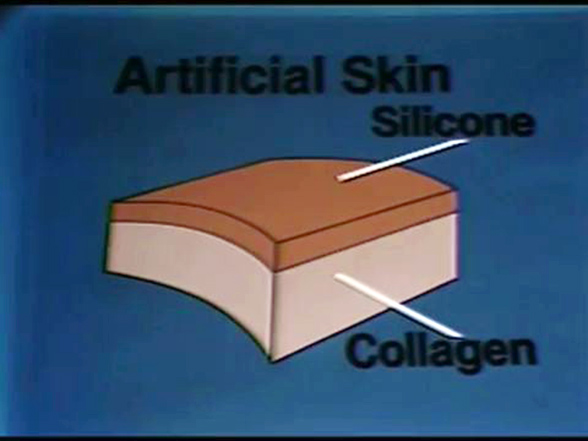

TRUMP: This picture shows comparatively the distribution and depth of the ionization-- this is depth-- produced by three kinds of electron sources. This rapidly diminishing one here represents the distribution in depth produced by the beta rays, which are electrons, from radioactive strontium-90. You see its dose is limited very close to the surface. It's very caustic on the skin.

These two curves, which seem to come to an end after a peak under the surface, represent the distribution and depth produced by electrons. The inner one is 2 and 1/2 million volt electrons, and the deeper one is 5 million volt electrons. And this curve, which seems to go quite deep in, distributing its ionization to 60 millimeters, let's say-- that's the end of the scale-- is the distribution and depth produced by 100 kilovolt x-rays, typically used in treatment of skin malignancies with x-rays.

The purpose of this was to show the extraordinary suitability of electrons for treating superficial disease, because no effect goes beyond their well-defined range, which can be adjusted to the thickness of the lesion by adjusting the voltage. This is now beginning to be used quite extensively around the country, and the Lahey Clinic, which has worked with MIT since 1949, has treated over 1,500 patients with direct injection of electrons into such situations. We have used electrons now for many other purposes, and, indeed, electrons have passed on to large-volume uses.

INTERVIEWER: Well, that's one of the things that I wanted to come to next, some other biological applications, as, for example, the inactivation of viruses in blood plasma. You might tell a little bit about that. There's a photograph of one of the pieces of equipment that's used for work of that sort.

TRUMP: This shows the business end, that is the output beam end, of our 3-million-volt Van de Graaf at MIT in the High Voltage Research Laboratory, taken probably around 1947 or so. We became interested in showing the ability of electrons to traverse through the final container of a pharmaceutical package, for example. These are several penicillin-containing vials and also some tubes containing surgical sutures.

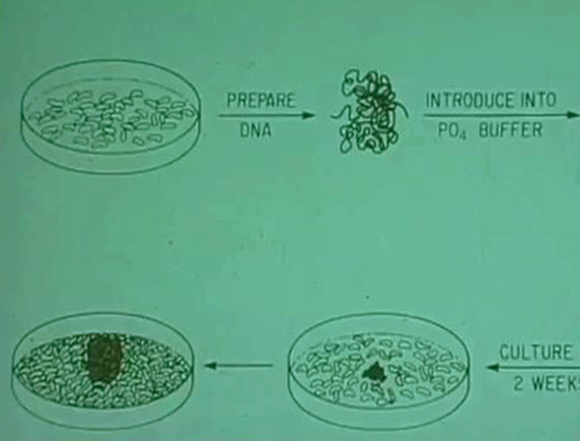

We demonstrated the ability to sterilize these materials so as to free them from unwanted organisms, but it became clear that electrons could do a very good job of sterilizing, in their final containers, many surgical and medical materials. We became interested also in studying, with the help of the virologists under Dr. John Enders of the Children's Hospital in Boston and the State Biological Laboratories in Massachusetts, the ability of electrons to destroy or inactivate hepatitis virus in blood plasma.

INTERVIEWER: That is the one that I think you were telling me about recently that experimental indications look as though it would be a very important adjunct, but we're not in a position to try it on human beings.

TRUMP: Unfortunately, about the time, we had become clear of two things. One is that we could take blood plasma from a patient with hepatitis in the highest stage of infectivity and knock out the hepatitis. And the other thing was that if we did this under the proper condition-- that is, with the plasma frozen-- we would not materially adversely affect its albumin or other contents, the lipoproteins and various fractions in the plasma. We unfortunately were not able to persuade anybody to try this. That is to do the critical experiment which would involve human volunteers, for the reason they did have some casualties among volunteers when they had tried materials that had been inadequately disinfected or inactivated by other methods.

INTERVIEWER: Gosh, I just hope that somehow a mechanism will be found for testing this because if some means can be developed for treating the hepatitis virus, just think of what it will mean to everybody. It's such a problem.

TRUMP: We learned a great deal about virus inactivation in those days because we couldn't work directly with hepatitis. We had to work with 15 other viruses. Polio, mumps, vaccinia, you name them. We did them. And we have a pretty good idea what hepatitis would take.

INTERVIEWER: Well, in somewhat the same direction, how about the question of food sterilization or preservation?

TRUMP: That's another thing we began to be very interested in beginning in 1946, and we worked with the Department of Food Science at MIT, now called Food Science and Nutrition, on food preservation. It was rather encouraging, and the ideas have clarified a great deal. Originality, we thought we had to sterilize food to preserve it, but now it is clear that you can give it a much lower dose than a sterilizing dose with less effect on its taste or color or other qualities and greatly increase the storage life of food, enough so as to be an important economic and public health procedure. But food sterilization is now being thoroughly studied, mainly by government laboratories such as the outstanding laboratory at Natick in Massachusetts.

INTERVIEWER: If you were to look at the economics of this, electron irradiation putting extremely high doses and in short periods would perhaps be superior to x-rays?

TRUMP: It would be much superior to x-rays because x-rays are efficiently produced only by using electrons. But the efficiency is low. At 2 million volts on a gold target, the conversion efficiency is only 5% or 6%, so you lose a factor of 20 in efficiency. You do get a more penetrating x-ray, but only 1/20 of the energy is effectively converted.

This is an economic cost you can't use. It therefore became of interest to us and also to a number of companies, including High Voltage Engineering Cooperation, with which I became actively interested after the war and was a participant in founding, to develop sources of electrons for such industrial purposes.

INTERVIEWER: I'm glad you brought up the question of High Voltage Engineering. I wanted to ask you about that and roughly when it got started and your connection with it. Your connections from the very outset have been very intimate, indeed.

TRUMP: They have been quite intimate. Perhaps High Voltage was a dream of mine during the war when I was elsewhere, but it became an actuality after the water. And it began operating in 1947 because there awaited me at MIT when I returned to this requests from several hospitals, one in England, the Sheffield Radio Center for Cancer Therapy in Sheffield, England, for assistance in building a 2-million-volt x-ray source. It was not feasible for MIT to help all the people who wanted to build one, so first I sought to find a company that was willing to do this based on our experience with the American Oncologic machine.

And when no company, among quite a few, was interested because of their preoccupation with their own reorientation to post-war affairs, Dr. Van de Graaf and I and Denis Robinson, an Englishman who had been a professor of electrical engineering at the University of Birmingham for a year after the war, united to form the High Voltage Engineering Corporation, first in Cambridge and now in Burlington, Massachusetts.

INTERVIEWER: Well, I wanted very much to get that in, and this leads directly into one other of your areas of intense concern. And this is the pushing of your high-voltage, high-energy generators up into the multimillion volt range, particularly for research on nuclear structure. And very briefly, I have three photographs here. Remembering the one that we saw, the 1 or 2 million volt set, which was roughly the same height as you, let's take a quick look at these two or three photographs here without much discussion.

TRUMP: This sketch shows the biggest of the large family of accelerators that high-voltage engineering produced. This was about 1967 and is called an Emperor Tandem. There about a dozen of these around the world at principal nuclear laboratories.

The Tandem accelerator starts with a positive ion source at this end, accelerates the ions to a high-voltage negative terminal, strips the electrons, or some of them, off of the positive-- it starts with a negative ion-- off the positive terminal and then off the negative ion and makes it a positive ion and then accelerates it away from this high-voltage negative terminal back to ground as an accelerated at twice the accelerated positive ion. In a case of heavy particles, you can strip more than one electron off. In fact, this system, the Emperor Tandem, produced particles with total energies up to 200 million electron volts on accelerating uranium.

INTERVIEWER: Now, I think that picture shows a man or a figure somewhere in there.

TRUMP: This picture shows the next stage, called the Transuranic accelerator, the TU accelerator. This was only recently reduced to commercial practice, but it was built about 1968 or so. The diameter of this steel tank was 25 feet, and it was 86 feet long. This lady who is cleaning up the bottom was put in there for dramatic effect to illustrate the size. This tank is built for 300 pounds per square inch pressure and to operate in sulfur hexafluoride gas, and this picture shows the same tank with the Van de Graaff tandem accelerator column in there. It's stretched in there between one end of the tank and the other, 86 feet apart, with the insulated terminal in the middle.

INTERVIEWER: So that the span between the supports is 40-some feet?

TRUMP: Between supports is 86 feet. It's compressed from both ends, but it has enough diameter that it makes a stiff, rigid column. But the insulating length on each side is about 30 feet, and the terminal length, which you can't see in this picture, is about 10 or 12 feet long, about 8 feet in diameter.

INTERVIEWER: Oh, absolutely remarkable, there's one other thing that we have a minute or two that I'd like to just have you bring in. This has to do with electron injection into materials and some of the interesting applications. That's a spectacular picture. Let's take a look at it.

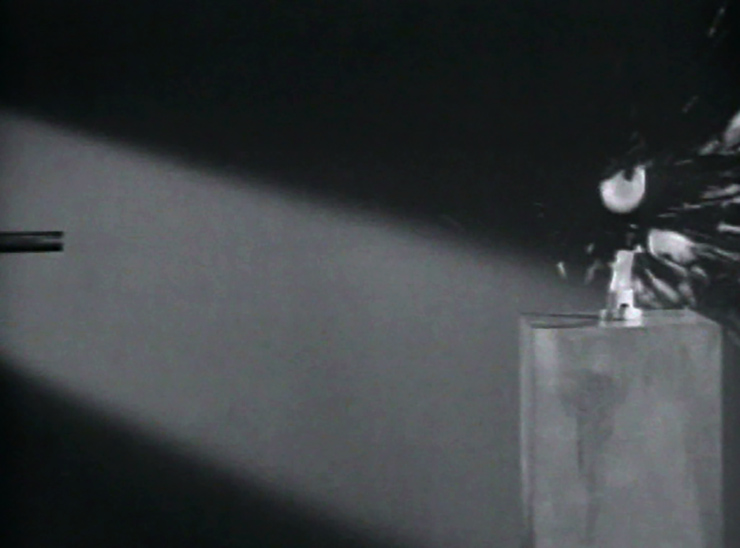

TRUMP: This is a beautiful drainage pattern, but it actually represents the drainage pattern produced in a block of clear Lucite after you have injected through its broad face a number of high-energy electrons, 3-million-volt electrons. Finally, these build an intense negative cloud within the volume, and if you produce a defect on the bottom edge of it, they will all discharge in a lightning flash-- and you can do this outside after injection-- and leave this permanent destructive pattern in the Lucite. It reminds one of the great drainage systems of nature, the drainage geological patterns you see when you look down on New Mexico and so forth, or the venous patterns in a leaf.

INTERVIEWER: Now, what are some of the practical applications of this? This is a spectacular experiment.

TRUMP: We were interested in dielectrics, and you can produce intense electric fields in this electrodeless method of charging an insulator. But it doesn't really have many practical applications that we have found as well. It's sort of something of great elegance that reminds us of the remarkable intricacy of nature and her ability to solve a complex problem, like producing such a discharge pattern in a microsecond, but we do not really have commercial applications other than the aesthetic and artistic ones, which are derived from looking at figures of that kind.

INTERVIEWER: Well, we'll just wait a little. They'll come. I'm sure of that. Well, there's one last thing that I would like to have you talk about a little bit. This is some of your pretty recent work, having to do with the treatment of municipal sludge, of all things. We've gone from the small microoperations of that now to the water plant dumps and whatnot. What about that?

TRUMP: I used to believe that anyone that thought you could use high-energy electrons to disinfect municipal sludge was barmy in the crumpet.

INTERVIEWER: I would have agreed with you.

TRUMP: But by four years ago, I was convinced it was economic and practical, and with wonderful support from the National Science Foundation, we have been investigating this, both at MIT in a scientific way, and at Deer Island, which is Boston's biggest treatment plant where we have an experimental electron disinfection facility capable of disinfecting, or designed to disinfect, one third of Deer Island's sludge. Disinfection means destroying the pathogens, the pathogenic bacteria, viruses, and parasites, in sludge so that it could be safely put on the land for its soil conditioning and agricultural benefits. It's very economic, and I'm happy to say that the city of Miami, through its Miami-Dade Water and Sewer Authority, is actively engaged in the second phase of design of such a facility.

INTERVIEWER: But when you stop to think of the enormous quantities of sludge that are produced in a day, and you're going to try to do something about that, in a few words, what how fast does this stuff move through your beam?

TRUMP: At Deer Island, the material flows at 6 feet a second as a wide, thin layer, passing once in a single pass through a scanning electron beam that covers the entire width of the layer, and the electrons have enough energy to go through the thickness of the layer. The material is a liquid. It's not composted. We eliminate a lot of processes. It is the anaerobically-digested, thickened sludge, about 5% solids, before any further chemical treatment and mechanical dewatering that we disinfect as a liquid flowing in this fashion.

INTERVIEWER: John, I would love to hear more about that. I think we've about used up our time here. In addition, I just wish that I could bring out-- and there isn't time-- many other areas of interest and achievement that you've had. You've just touched the ones having to do with electron accelerators, let us say.

I happen to know that there are various other fields that are maybe even more extensive in their applications than that. So we'll have to stop, and I want very much to thank you for having taken the time and trouble to come here, tell us a little bit about the background of your work, and I'm sure inspire some of the young people who are going to one time or another see this taping. Thank you very, very much.

TRUMP: Thank you, Lauri. I've enjoyed it enormously.

[MUSIC PLAYING]